OUR FACTORY

Our factory occupies 15,000 square meters of a total land area of 40,000 square meters. With a dedicated workforce of over 350 skilled employees, we maintain a high level of productivity, efficiently managing the production of 40 to 60 containers per month. This expansive and well-organized facility enables us to meet production demands while upholding our commitment to quality and operational excellence.

WAREHOUSE

The warehouse spans an area of 1,000 square meters, offering a spacious and well-maintained environment for storing raw materials. All incoming materials undergo a thorough quality inspection upon arrival to ensure they meet our strict standards before being introduced into the production process.

SHAPING – ASSEMBLY

Our factory is equipped with a high-performance machinery system dedicated to the shaping and assembly stages. We utilize advanced CNC, sanding and UV machines to ensure precision, consistency, and superior surface quality.

To enhance efficiency and craftsmanship, we operate specialized production lines tailored to specific product categories—including cabinets, beds, dining tables, and chairs. This structure allows our skilled technicians to focus on their area of expertise, delivering well-crafted furniture that meets the diverse needs of our clients.

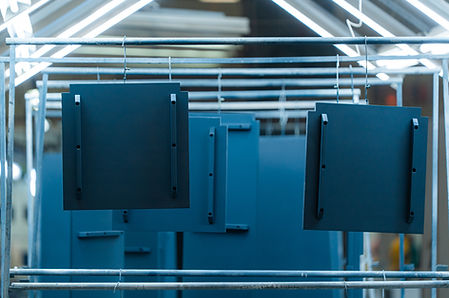

FINISHING

Our factory is equipped with two advanced Cartline systems, totaling 600 carts, and a smoothly running hanging line that keeps everything moving efficiently through the finishing area. Once assembled, products are transferred to the paint spraying line for a high-quality finish, followed by a thorough in-process quality check to ensure they meet our standards. This attention to detail at every step, combined with a final inspection, helps us maintain consistency, efficiency, and top-notch quality in everything we produce.

PACKING

To ensure our qualified furniture pieces arrive in perfect condition, we carefully wrap them in protective material and add Styrofoam to the corners for extra safety. Our packing process adheres to strict international guidelines to provide reliable protection throughout transit.